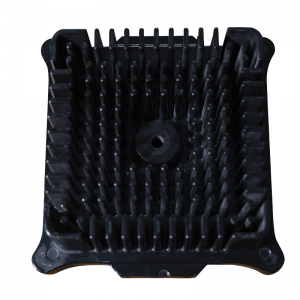

Die-cast custom heatsink for Radiator

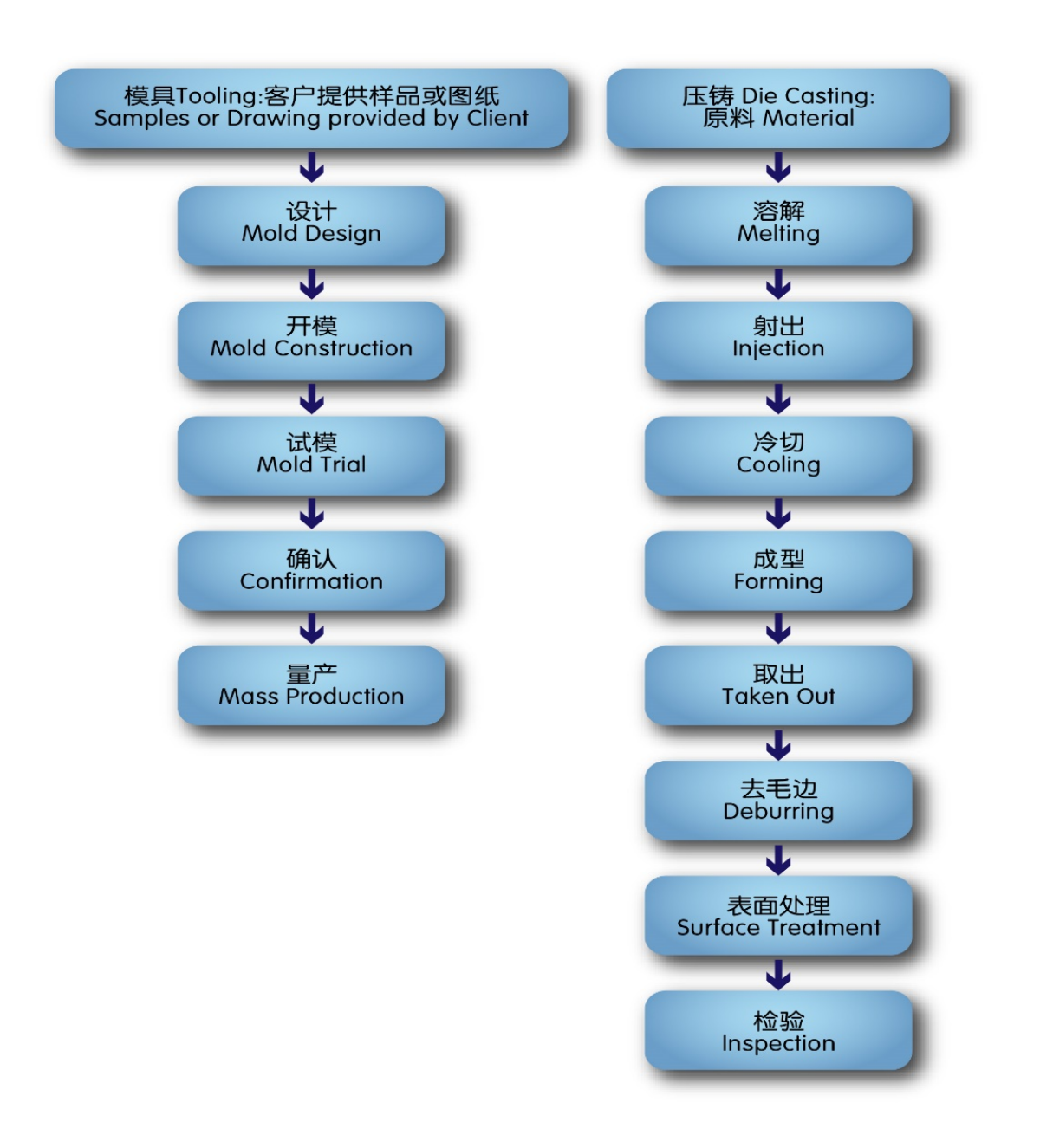

The process of heat sink

Tooling design

High pressure die casting

Trimming

Deburring

Sand blasting

Surface polishing

Powder Coating

CNC tapping & machining

Helical insert

Surface Treatment

1. Chemical oxidation

2. Painting

3. Electrophoresis

4. Anodizing

5. Powder coating

Die cast heat sinks

Die cast heat sinks are perfect if you need a custom designed aluminum heat sink . They are manufactured by forcing liquid aluminum under high pressure into steel molds .Die casting heat sink is popular in the market because it was made from aluminum alloy. This is the preferred material for die casting heat sink. These die casting processes are suitable to meet every project requirement and performed rapid production.

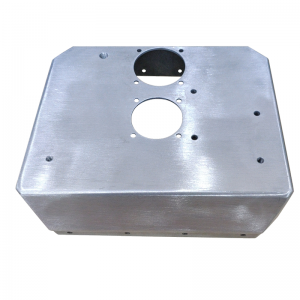

Fast lead time only 35-40 days

High Performance on anodized surface finishes

High tight dimensions controlled within +/-0.05mm

Engineers help to finalized from design to manufacturing

Benefits of Die Cast Heat Sinks

Compared with other manufacturing methods, die casting offers the following benefits:

1.Produce complex 3D shapes that are not possible in extrusion or forging

aluminum heat sink, frame, housing, enclosure and fastening elements can be combined in a single casting

2.Holes can be cored in die casting

3.High production rate and low cost

4.Tight tolerances

5.Dimensionally stable

6. Secondary machining not required

Provide exceptionally flat surfaces (good for the contact between heat sink and source)

Corrosion resistance rates from good to high

Kingrun process flow

Compared with other manufacturing methods, die casting offers the following benefits:

1.Produce complex 3D shapes that are not possible in extrusion or forging

Heat sink, frame, housing, enclosure and fastening elements can be combined in a single casting

2.Holes can be cored in die casting

3.High production rate and low cost

4.Tight tolerances

5.Dimensionally stable

6. Secondary machining not required

Provide exceptionally flat surfaces (good for the contact between heat sink and source)

Corrosion resistance rates from good to high

Excellent EMI an RFI shielding