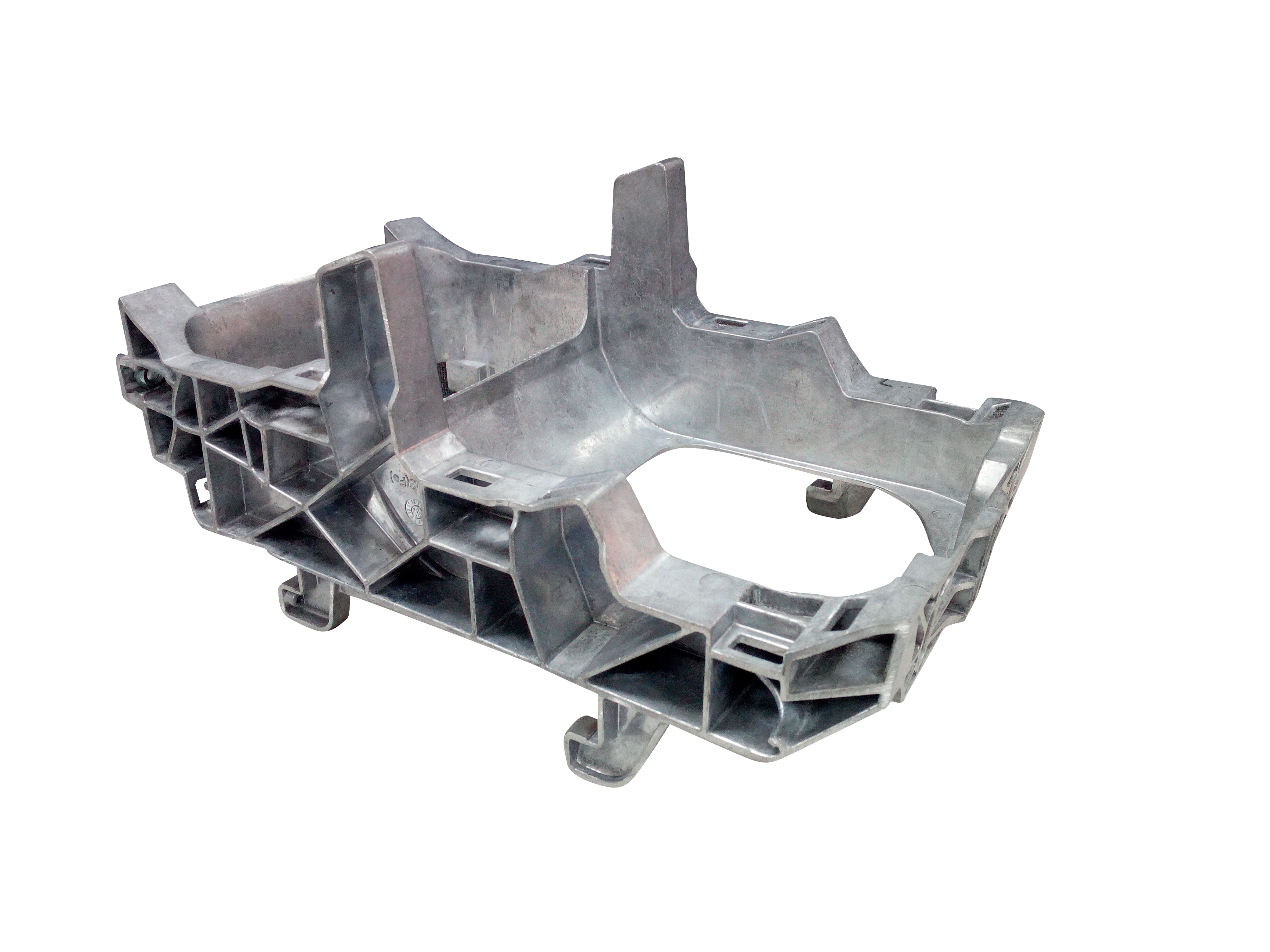

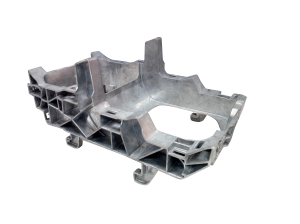

Aluminum high pressure die casting base for auto parts

Product Details

| Processing | High Pressure Die CastingTrimmingDeburringShot blastingSurface polishingCNC machining ,tapping ,turningDegreasingInspection for size |

| Machinery | Die casting machine from 450~1650tonsCNC Machines 60 sets including brand Brother and LGMazakDrilling machines 6 setsTapping machines 5 setsDegreasing lineAutomatic impregnation lineAir tightness 8setsPowder coating lineSpectrometer (raw material analysis)Coordinate-measuring machine (CMM)X-RAY ray machine to test air hole or porosityRoughness testeraltimeterSalt spray test |

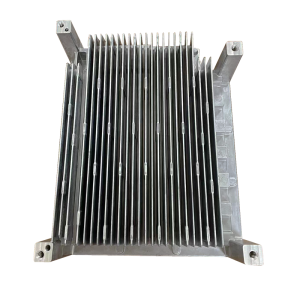

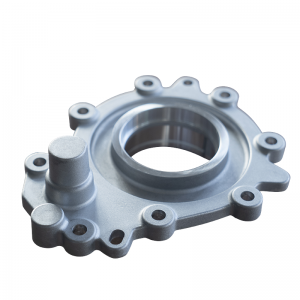

| Application | Aluminum housings ,motor cases, battery cases of electric vehicles, aluminum covers ,gearbox housings etc. |

| Applied file format | Pro/E, Auto CAD ,UG, Solid work |

| Lead time | 35-60 days for mold , 15-30 days for production |

| Main export market | Western Europe ,Eastern Europe |

| Company advantage | 1) ISO 9001, IATF16949,ISO14000

2) Owned die casting and powder coating workshops 3) Advanced equipment and excellent R&D Team 4) Highly skilled manufacturing process 5) A broad variety of ODM&OEM product range 6) Strict quality Control System |

Procedures of Die Casting Production

1. Inquiry- Check all requirements are clear -->

2. Quote based on 2D and 3D drawing-->

3. Purchase Order Released-->

4. Mold design and production issues confirmed--->

5. Mold making-->

6. Part Sampling-->

7. Sample Approved-->

8. Mass production--->

9. Parts delivery

Die Castings FAQ

1.What are the Differences Between Aluminum Die Casting vs. Sand Casting?

The most significant difference between die casting and sand casting is the mold-making material. Aluminum casting uses a mold made of aluminum alloy. On the other hand, sand casting uses a mold made of sand.

Sand casting is capable of working with more complex designs. On the other hand, die casting offers more dimensional accuracy and speed.

Another vital difference is, sand casting produces thicker walls whereas die casting can produce thinner walls. Therefore, sand casting is not ideal for small parts.

Production speed is another vital difference between these two techniques. Die casting tooling is a complex task and needs a considerable amount of time. On the other hand, sand casting tooling is a simple process and needs less time than die casting.

Die casting is ideal for large-scale production like if you need thousands of parts. But sand casting is ideal for small-scale production like 100-150 units.

2. How Expensive is Aluminum Casting?

Aluminum casting is one of the most cost-effective metal die-casting processes. Though the tooling of die casting needs more time, you can create thousands of units with one mold. The more you produce, the less becomes your unit price. Aluminum is much cheaper than stainless steel and slightly more expensive than carbon steel.

3.How fast is the die casting process?

Die casting is an automated casting process. It takes a while to create the mold. But the mold can solidify aluminum alloy quickly. And as it is an automated process, the machine can manufacture many units without taking any break. Therefore, die casting is a fast process especially when you are manufacturing a huge number of parts.

Our factory view

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com