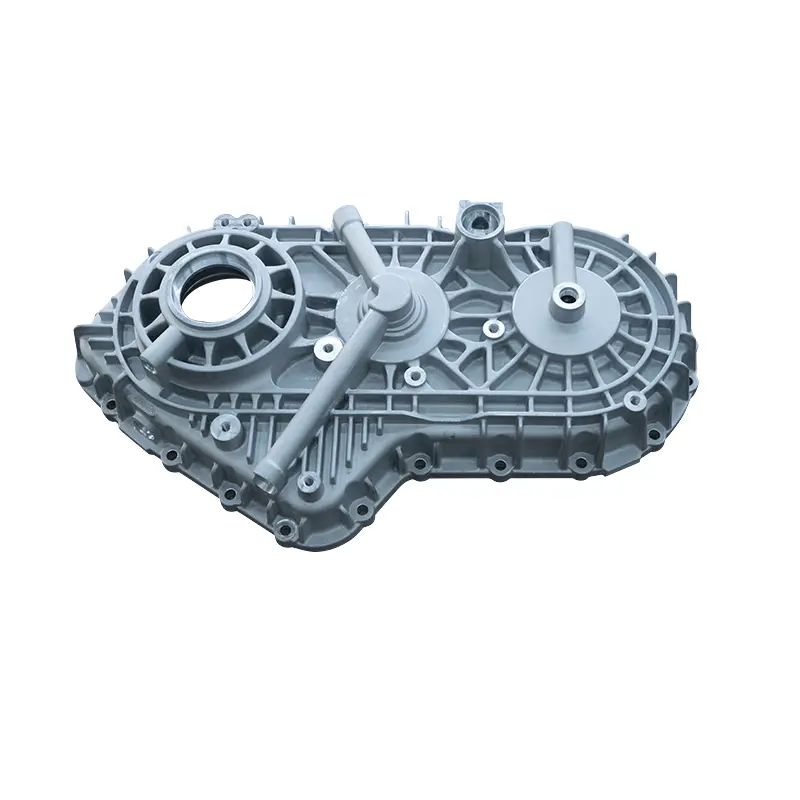

In the world of automotive parts, precision and quality are paramount. From the initial design to the final product, each component undergoes a meticulous manufacturing process to ensure optimal performance. One such crucial element is the aluminum gear box housing. In this blog, we will delve into the intricate world of mold machining, the importance of prototypes, and the stringent quality standards that make aluminum gear box housings excel in the automotive industry.

The Art of Mold Machining

Mold machining plays a pivotal role in creating the aluminum gear box housing. With the aid of the latest equipment, molds are carefully fabricated to the closest tolerances. This precision allows for the creation of flawless gear systems, ensuring seamless operations within the automotive transmission. The process involves utilizing advanced techniques like computer numerical control (CNC) machining to achieve the desired shapes and dimensions. Expert machinists with a keen eye for detail employ their skills to craft molds that will later produce the gear box housings. The immaculate surface finishes, intricate designs, and exact measurements are all achieved through the art of mold machining.

The Prototype Advantage

Customers often require a prototype of the aluminum gear box housing to ensure it meets their expectations. This step helps to identify any design flaws, make necessary improvements, and tailor the product to the customer’s requirements. Prototypes also enable engineers to analyze the housing’s compatibility with the overall automotive system and assess its durability. By creating a prototype, manufacturers can fine-tune the design and make any necessary adjustments before full-scale production. This ensures cost-effectiveness and customer satisfaction, while also minimizing the risk of potential defects or recalls.

A Commitment to Quality

Quality is the cornerstone of the aluminum gear box housing manufacturing process. From material selection to final assembly, manufacturers adhere to stringent quality control measures. Every stage is monitored and tested to ensure that the finished product meets or exceeds industry standards. Advanced quality inspection equipment is utilized to detect any deviations from specifications, guaranteeing that each gear box housing is flawless in function and appearance. Manufacturers also conduct rigorous performance tests, simulating real-world conditions before any product is introduced to the market. This commitment to quality ensures the reliability and longevity of the aluminum gear box housing, satisfying both manufacturers and end-users alike.

The automotive industry relies on precision, performance, and excellence. The production of aluminum gear box housings exemplifies this dedication to perfection. Through meticulous mold machining, the creation of prototypes, and unwavering commitment to quality, manufacturers ensure that each gear box housing stands up to the demands of the automotive world. With advancements in manufacturing techniques and ever-evolving industry standards, aluminum gear box housings continue to be at the forefront of automotive advancements, offering durability, reliability, and seamless operations.

Post time: Aug-03-2023