Close Tolerance CNC Machining for Casting and Custom Parts

What is CNC Machining?

CNC(Computer Numerical Control)which is an automated manufacturing process that controls and operates machinery—such as lathes, mills, drills, and more—by way of a computer. It has evolved the manufacturing industry as we know it, streamlining the production process and allowing complex tasks to be done with precision and efficiency.

CNC is used to operate a range of complex machinery, such as grinders, lathes, turning mills and routers, all of which are used to cut, shape, and create different parts and prototypes.

Kingrun utilizes customs CNC machining for finishing or fine-tuning die cast parts. While some die cast parts require only simple finishing processes, such as drilling or metal removal, others need high-precision, post machining to achieve the part’s required tolerance or improve its surface appearance. With plenty of CNC machines, Kingrun performs in-house machining on our die cast parts, making us the convenient single-source solution for all your die casting needs.

CNC Process

The CNC machining process is fairly straightforward. The first step is engineers designing the CAD model of the part(s) you need for your project. The second step is machinist turning this CAD drawing into the CNC software. Once the CNC machine has the design you will need to prepare the machine and the final step would be executing the machine operation. An additional step would be to inspect the completed part for any errors. CNC Machining can be broken into various types, mainly including:

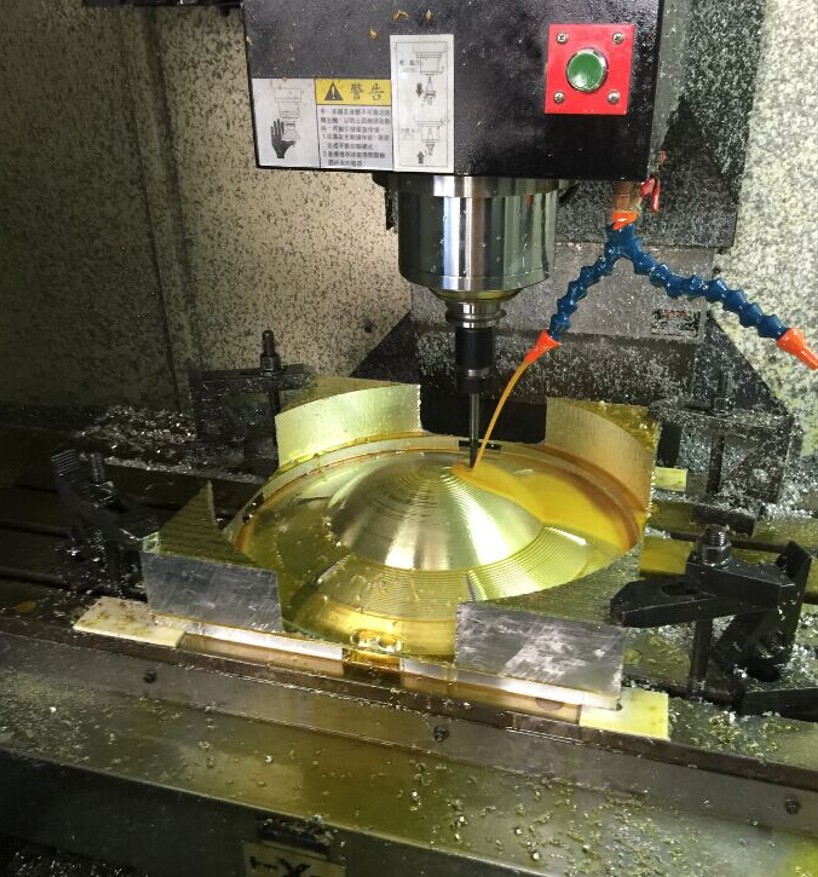

CNC Milling

CNC milling rapidly rotates a cutting tool against a stationary workpiece. The process of subtractive machining technology then works by the material being removed from the blank workpiece by cutting tools and drills. These drills and tools rotate at high speed. Their purpose is to remove material from the workpiece using instructions originating from the CAD design in the early stages of development.

CNC Turning

The workpiece is kept in position on the spindle while rotating at high speed, while the cutting tool or central drill traces the inner/outer perimeter of the part, forming the geometry. The tool does not rotate with CNC Turning and instead moves along polar directions radially and lengthwise.

Almost all materials can be CNC machined; the most common material we can do includes:

Metals - Aluminum(Aluminium)alloy: AL6061, AL7075, AL6082, AL5083,steel alloy, stainless steel and brass, copper

Our capability of CNC machining

● Possesses 130 sets of 3-axis, 4-axis and 5-axis CNC machines.

● CNC lathes, milling, drilling and taps, etc. fully installed.

● Equipped with a processing center that automatically handles small batches and large batches.

● The standard tolerance of components is +/- 0.05mm, and tighter tolerances can be specified, but pricing and delivery may be affected.